Inventory turnover management serves as a crucial aspect of business operations, reflecting how efficiently a company can sell and replace its stock. By mastering this metric, businesses can enhance profitability, reduce holding costs, and streamline supply chain processes. Understanding the nuances of inventory turnover not only helps in assessing performance but also drives strategic decisions across various industry sectors.

This overview delves into the fundamentals of inventory turnover, innovative practices in inventory management, and the diverse approaches taken by businesses around the globe. From leveraging technology to exploring international management techniques, there’s a wealth of knowledge to optimize inventory levels and boost overall performance.

Inventory Turnover Management Fundamentals

Inventory turnover is a crucial metric that reflects how effectively a business manages its inventory. It measures the number of times inventory is sold and replaced over a specific period. A high inventory turnover rate indicates efficient management, while a low rate may suggest overstocking or weak sales. Understanding this concept is vital for businesses aiming to optimize their operations and maximize profitability.The formula for calculating inventory turnover is straightforward:

Inventory Turnover = Cost of Goods Sold (COGS) / Average Inventory

The components of this formula include the Cost of Goods Sold, which represents the direct costs attributable to the production of the goods sold, and Average Inventory, calculated as the sum of beginning and ending inventory values divided by two. Different industries exhibit varying inventory turnover ratios. For instance, retail businesses typically have higher turnover rates due to fast-moving consumer goods, while industries such as manufacturing or heavy machinery may experience lower ratios due to longer sales cycles and larger stock holding requirements.

Business Innovation in Inventory Management

Innovative strategies are essential for companies looking to enhance their inventory turnover. By leveraging technology and modern practices, businesses can significantly improve their efficiency. Some effective strategies include:

- Implementing Just-In-Time (JIT) inventory systems to minimize stock levels and reduce holding costs.

- Utilizing data analytics to forecast demand accurately, allowing for better inventory planning.

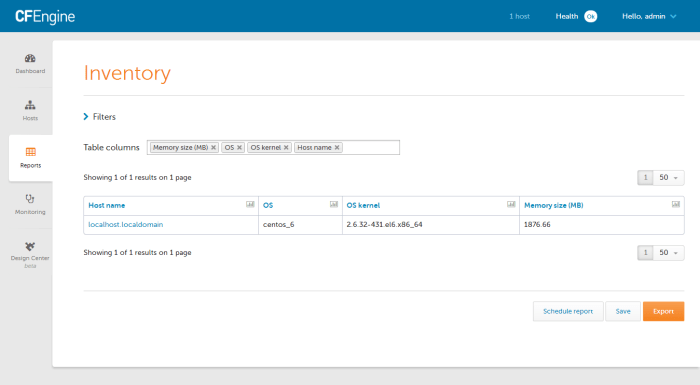

- Adopting automated inventory management systems to track stock levels in real-time.

Several technologies have emerged that enhance inventory tracking and management, including:

- RFID (Radio Frequency Identification) technology, which improves accuracy and efficiency in stock management.

- Cloud-based inventory management software that allows for seamless access to inventory data across multiple locations.

- Machine learning algorithms that analyze sales patterns and optimize stock levels accordingly.

Examples of successful companies that have excelled in inventory turnover through innovation include Amazon, which uses sophisticated algorithms for stock management, and Zara, known for its rapid stock replenishment system that responds quickly to fashion trends.

International Business and Inventory Practices

Inventory turnover management practices can vary significantly across countries, influenced by cultural norms, regulations, and market conditions. For instance, companies in Japan often emphasize lean inventory practices, focusing on waste reduction and efficiency, while businesses in the United States may prioritize speed and responsiveness to market demand.Global supply chains have a profound impact on inventory turnover. Companies must navigate complexities such as transportation delays, tariff regulations, and varying supplier capabilities, which can affect stock levels and turnover rates.

As businesses expand internationally, they face challenges like managing diverse supplier relationships and adapting to local consumer preferences.

Business Interviews Related to Inventory Management

When interviewing for inventory management roles, it’s crucial to ask questions that reveal a candidate’s ability to handle the complexities of inventory management. Potential interview questions might include:

- What experience do you have with inventory management software?

- How do you handle discrepancies between physical inventory and inventory records?

- Can you describe a time when you improved inventory turnover at a previous job?

Key skills and qualifications critical for success in inventory management roles include a strong understanding of supply chain principles, analytical thinking, and proficiency with relevant software tools. Industry experts suggest that effective inventory turnover strategies often involve continuous learning and adaptability to new technologies and practices.

Job Search Techniques for Inventory Management Roles

To successfully secure a position in inventory management, candidates should possess specific qualifications, such as a degree in supply chain management or business administration and experience with inventory control systems. Highlighting relevant experience on a resume is essential for standing out to potential employers.Tailoring a resume for a career in inventory management involves focusing on quantifiable achievements, such as improvements in inventory turnover rates or cost reductions through efficient inventory practices.

Job seekers should also emphasize their ability to work collaboratively across departments, as inventory management often requires coordination with sales, purchasing, and operations.Tips for job seekers include networking within the industry, attending relevant workshops, and joining professional organizations that specialize in supply chain and inventory management. Engaging with experts and peers can provide valuable insights and opportunities for career advancement.

Business Management and Inventory Control

Inventory management plays a critical role in overall business management. Efficient inventory practices contribute to cost savings, improved cash flow, and enhanced customer satisfaction. By integrating inventory turnover strategies into business plans, companies can ensure that they align their operational goals with their inventory control efforts.Key performance indicators (KPIs) related to inventory management include:

- Inventory turnover ratio

- Days inventory outstanding (DIO)

- Gross margin return on investment (GMROI)

Monitoring these KPIs helps businesses assess their inventory efficiency and identify areas for improvement.

Marketing Direct and Inventory Turnover

Effective marketing can significantly influence inventory turnover rates. By creating demand through targeted marketing strategies, businesses can move inventory more quickly. The relationship between sales promotions and inventory turnover is evident; successful promotions can lead to increased sales, which in turn accelerates inventory turnover.Examples of marketing strategies that have successfully improved inventory turnover include:

- Seasonal sales that clear out older inventory to make way for new products.

- Bundling products to encourage higher sales volumes.

- Utilizing social media campaigns to drive engagement and interest in products.

Such approaches demonstrate how marketing initiatives can directly impact inventory dynamics, leading to more responsive inventory management.

Business Networking for Inventory Professionals

Building a professional network is vital for inventory management professionals seeking to advance their careers. Networking can provide insights into industry trends, job opportunities, and best practices. Attending industry conferences focused on inventory management offers numerous benefits, including networking opportunities, learning about new technologies, and gaining insights from leading experts in the field. Engaging with peers during these events fosters collaboration and knowledge sharing.Mentoring can also play a crucial role in advancing inventory management careers.

Establishing connections with experienced professionals allows for guidance and support in navigating the complexities of inventory management.

Business Outsourcing and Its Impact on Inventory

Outsourcing has become a common practice in inventory management, allowing companies to focus on core business functions while leveraging the expertise of third-party logistics providers. This strategy can lead to improved efficiency and reduced costs in managing inventory.Comparing in-house and outsourced inventory management solutions highlights the pros and cons of each approach. In-house management allows for greater control and customization, while outsourcing can provide access to advanced technologies and expertise without the overhead costs.However, outsourcing inventory management functions comes with risks, such as potential service quality issues and less direct oversight.

Companies must weigh these risks against the benefits to determine the best approach for their inventory needs.

Business Presentations on Inventory Performance

Creating effective presentations on improving inventory turnover is essential for communicating strategies and results to stakeholders. A well-structured presentation should include clear data and visuals that highlight key findings and recommendations.Data visualization plays a crucial role in communicating inventory management strategies. Utilizing charts and graphs can help convey complex information in an easily digestible format, enhancing understanding and engagement.When delivering presentations on inventory metrics, it’s important to focus on clarity and conciseness.

Engaging the audience with relevant examples and interactive elements can also enhance the overall effectiveness of the presentation.

Business Productivity and Inventory Efficiency

Enhancing productivity through better inventory turnover management is achievable by implementing streamlined processes and effective tracking systems. Efficient inventory practices can lead to reduced lead times, improved order fulfillment, and increased customer satisfaction.The overall impact of efficient inventory practices on business productivity is significant. When inventory is managed effectively, the entire supply chain operates more smoothly, resulting in cost savings and improved cash flow.Tools that facilitate improved management of inventory workflow include inventory management software, barcode scanning systems, and data analytics platforms.

These technologies enable businesses to optimize their inventory processes and enhance overall efficiency.

Inventory Turnover in the Restaurant Industry

The restaurant sector faces unique challenges concerning inventory turnover. Perishable inventory requires careful management to minimize waste and ensure product freshness. Strategies for managing perishable inventory effectively include implementing first-in-first-out (FIFO) practices and closely monitoring stock levels.Successful inventory management in restaurants has been exemplified by various establishments that have streamlined their processes. For instance, some restaurants employ technology to track inventory in real-time, ensuring that they only order what is necessary based on sales trends.

Resumes and Cover Letters for Inventory Roles

When applying for inventory management positions, candidates should use tailored templates for their resumes that highlight relevant experience and skills. Including specific accomplishments related to inventory turnover can strengthen a resume’s impact.A cover letter that emphasizes inventory management skills should showcase a candidate’s understanding of inventory strategies and their ability to contribute to operational efficiency. Highlighting quantifiable achievements provides a compelling narrative to potential employers.Job seekers should also focus on showcasing their relevant experience in terms of inventory management, emphasizing metrics and outcomes.

This approach increases the likelihood of standing out in a competitive job market.

Business Retail and Inventory Management

Best practices for inventory turnover in the retail sector include maintaining optimal stock levels, understanding consumer behavior, and utilizing data analytics to forecast demand accurately. Retail businesses that successfully manage their inventory can respond effectively to changes in market demand.Consumer behavior significantly impacts inventory management. Retailers must adapt their inventory strategies based on trends and preferences to ensure that they have the right products available at the right time.Successful retail case studies demonstrate high inventory turnover rates by employing effective promotional strategies and utilizing technology to streamline inventory processes.

Such examples serve as inspiration for other businesses aiming to enhance their inventory management practices.

Risk Management in Inventory Control

Poor inventory turnover can lead to various risks, including increased holding costs, stockouts, and lost sales. Identifying these potential risks is essential for businesses aiming to maintain efficient inventory management practices.Strategies for mitigating risks in inventory management include implementing robust forecasting methods, conducting regular inventory audits, and maintaining strong relationships with suppliers. These practices help ensure timely stock replenishment and minimize disruptions.Examples of risk management frameworks applied to inventory control often incorporate technology and data analytics to identify and address potential issues proactively.

Such frameworks enable businesses to respond swiftly to changes in demand and supply conditions.

Business Sales and Inventory Turnover

There is a clear correlation between sales strategies and inventory turnover rates. Effective sales techniques can drive demand and improve inventory performance, leading to a more efficient overall operation.Sales techniques that can enhance inventory turnover include upselling and cross-selling, which encourage customers to purchase additional items, and employing dynamic pricing strategies to stimulate sales during slower periods.Metrics to evaluate the effectiveness of sales in inventory turnover encompass sales conversion rates, average order value, and inventory turnover ratios.

Monitoring these metrics allows businesses to refine their sales approaches and align them with inventory management goals.

Sales Management and Inventory Coordination

Sales management plays a vital role in optimizing inventory turnover. By aligning sales strategies with inventory management efforts, businesses can ensure that they meet customer demands without overstocking products.Tools that align sales and inventory management efforts include integrated software platforms that provide real-time data on inventory levels and sales performance. This integration facilitates better decision-making and resource allocation.Effective communication between sales and inventory teams is crucial for maintaining a cohesive approach to inventory management.

Regular meetings, shared dashboards, and collaborative planning sessions can enhance coordination and ensure alignment of goals.

Sales Teleselling Techniques and Inventory Insights

Telesales teams should be equipped with knowledge about current inventory levels during customer interactions. Understanding inventory status allows them to provide accurate information and manage customer expectations effectively.The importance of inventory knowledge in teleselling conversations cannot be overstated. Sales representatives who can discuss inventory availability confidently can enhance customer trust and increase sales.Successful teleselling strategies that consider inventory turnover include promoting items that are in stock and using urgency to encourage purchases, such as limited-time offers on fast-moving inventory.

Sales Training Focused on Inventory Awareness

A well-structured training program for sales teams about the importance of inventory turnover is essential for aligning sales efforts with inventory management goals. Training should focus on the relationship between inventory practices and sales performance.Incorporating inventory management education into sales training helps ensure that sales teams understand the implications of their actions on inventory levels. This understanding can lead to more thoughtful selling practices.Resources for ongoing sales training related to inventory management can include workshops, online courses, and access to industry publications.

Continuous learning fosters awareness and adaptability to changing market conditions.

Business Security and Inventory Management

The security risks associated with inventory management can significantly impact a business’s bottom line. Theft, loss, and damage to inventory are common concerns that require proactive measures.Preventive measures for safeguarding inventory include implementing security systems, conducting regular inventory audits, and training employees on best practices for securing stock. Such measures help deter theft and minimize losses.Conducting thorough inventory security assessments can ensure that businesses are aware of vulnerabilities and can implement the necessary safeguards to protect their valuable assets.

Small Business Strategies for Inventory Turnover

Small businesses face specific inventory management challenges, such as limited resources and fluctuating demand. Implementing effective strategies tailored to their unique circumstances is crucial for improving inventory turnover.Cost-effective inventory management solutions for small enterprises may include leveraging technology, such as inventory management software, to gain better insights into stock levels and sales trends.Examples of small businesses that have successfully improved their inventory turnover demonstrate the effectiveness of strategic planning and agile inventory practices.

These case studies serve as valuable learning opportunities for other small business owners.

Solo Professionals and Inventory Management

Solo professionals, such as freelancers or consultants, can manage inventory efficiently by utilizing simple tools and resources that cater to their specific needs. Maintaining organized records and utilizing cloud-based solutions can streamline inventory management processes.Available tools for individual inventory management may include spreadsheet applications for tracking stock levels and invoicing software that integrates inventory management functionalities.Tips for maintaining inventory records as a solo professional include setting regular review schedules, using barcode systems for easy tracking, and automating repetitive tasks to save time and reduce errors.

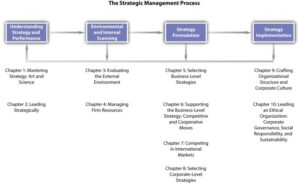

Strategic Planning for Inventory Management

Creating a strategic plan template for improving inventory turnover involves setting clear objectives, identifying key performance indicators (KPIs), and outlining actionable steps to achieve desired outcomes.Long-term goals for inventory management within a strategic framework should focus on fostering efficiency, reducing costs, and aligning inventory practices with overall business objectives.Successful strategic initiatives focused on inventory turnover can include process improvements, technology adoption, and employee training programs that enhance inventory management capabilities.

Team Building around Inventory Practices

Teamwork is essential for managing inventory effectively, as collaboration among different departments can lead to improved communication and operational efficiency.Organizing team-building activities that enhance inventory management collaboration can foster a sense of unity and shared purpose among staff. Activities might include workshops and joint problem-solving sessions that focus on inventory challenges.Effective communication strategies, such as regular updates and shared platforms for tracking inventory metrics, can nurture teamwork and ensure that all team members are aligned in their inventory management efforts.

Venture Capital and Inventory Management Solutions

Investment opportunities focused on inventory management technologies are on the rise, as businesses seek innovative solutions to optimize their processes. These technologies can lead to significant improvements in efficiency and cost savings.Trends in venture capital related to inventory optimization highlight the growing interest in automation, data analytics, and artificial intelligence solutions that enhance inventory management capabilities.Case studies of startups that have successfully secured funding for inventory solutions illustrate the potential for innovation in this field.

Companies leveraging advanced technologies to streamline inventory processes are often at the forefront of industry advancements.

Workplace Communication and Inventory Management

Effective communication within inventory management teams is crucial for ensuring that all members are aligned and informed about inventory practices and changes.Methods for enhancing communication between departments related to inventory include establishing clear protocols, utilizing collaborative platforms, and scheduling regular inter-departmental meetings to discuss inventory strategies.Tools that facilitate better communication in inventory processes may include project management software, internal messaging platforms, and shared dashboards that display real-time inventory metrics.

Workplace Safety in Inventory Handling

Safety protocols related to inventory management practices are essential for protecting employees and minimizing accidents. Establishing clear guidelines for handling inventory safely can create a safer workplace environment.Training employees on safe inventory handling is critical in preventing accidents and ensuring compliance with safety regulations. Ongoing training sessions can reinforce safety practices and empower employees to prioritize safety.A checklist for ensuring safe inventory management environments should include regular safety audits, employee training records, and feedback mechanisms that encourage staff to report safety concerns or incidents.

Epilogue

In summary, effective inventory turnover management is not just about numbers but about integrating various strategies that align with a company’s goals. By staying informed on best practices, embracing innovative technologies, and understanding the unique challenges within different markets, businesses can achieve remarkable improvements in their inventory efficiency. This comprehensive approach ensures not only survival but thriving in a competitive marketplace.

FAQ Explained

What is inventory turnover?

Inventory turnover is a financial metric that measures how many times a company’s inventory is sold and replaced over a specific period.

Why is inventory turnover important?

High inventory turnover indicates efficient management and strong sales, while low turnover can suggest overstocking or decreased demand.

How can I improve my inventory turnover?

Improvement can be achieved through better demand forecasting, optimizing stock levels, and enhancing sales strategies.

What industries typically have higher inventory turnover?

Retail and fast-moving consumer goods (FMCG) industries often experience higher inventory turnover compared to manufacturing or luxury goods sectors.

What are common inventory turnover benchmarks?

Benchmarks vary by industry, but generally, a turnover rate of 5 to 10 is considered healthy for retail businesses.